Is how I spent last Tuesday.

Well, last Tuesday..

We had a fire ring fail on the Cornell. On the 278A there is a copper fire ring on top of the cylinder, outside of which is the head gasket. The fire ring failed causing the O rings on the water jumpers between the liner and head to melt, which caused exhaust gas to get into the water side (causing the expansion tank to let off a few times before we got to it). We had the parts overnighted from Hatch & Kirk in Seattle WA....well, we tried..After spending the better part of a day trying to find a supplier (Thanks P)..we ordered the kit for rush overnight...guy forgot to place the order at H&K. After a few phone calls over Chinese dinner finding out where they are we got them the next day. We also redid the liner O rings as well while it was apart.

Anyway..

Draining the engine down.

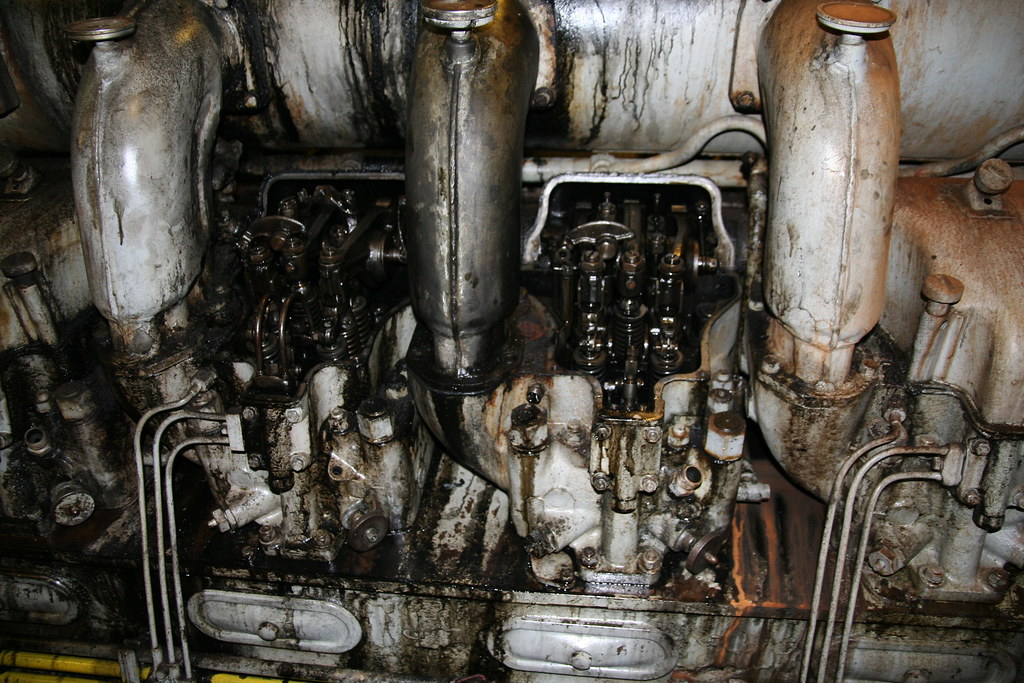

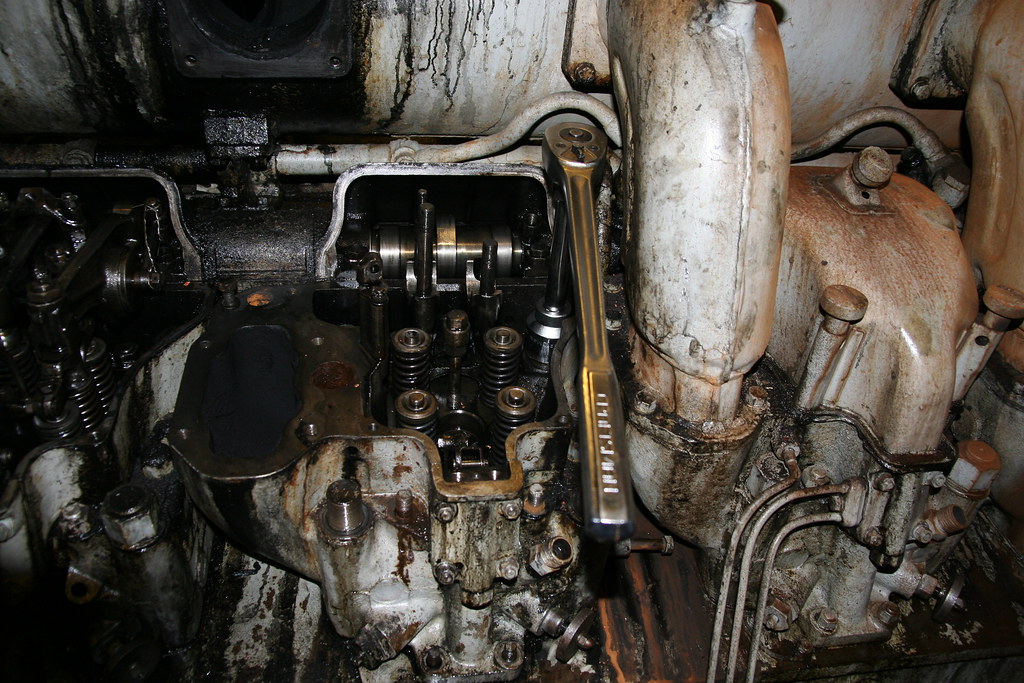

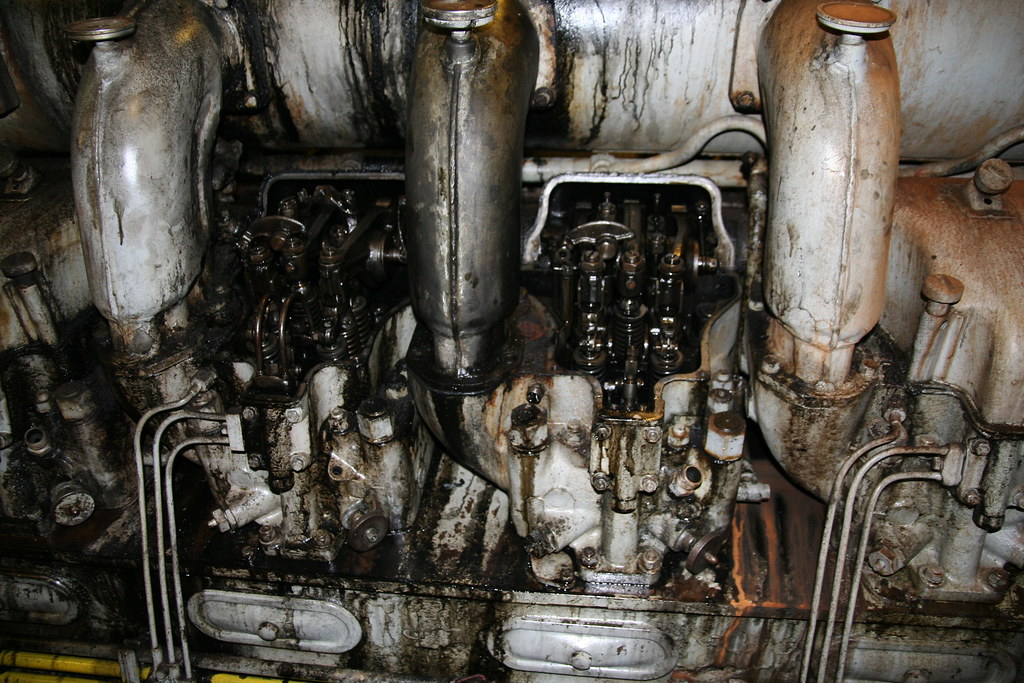

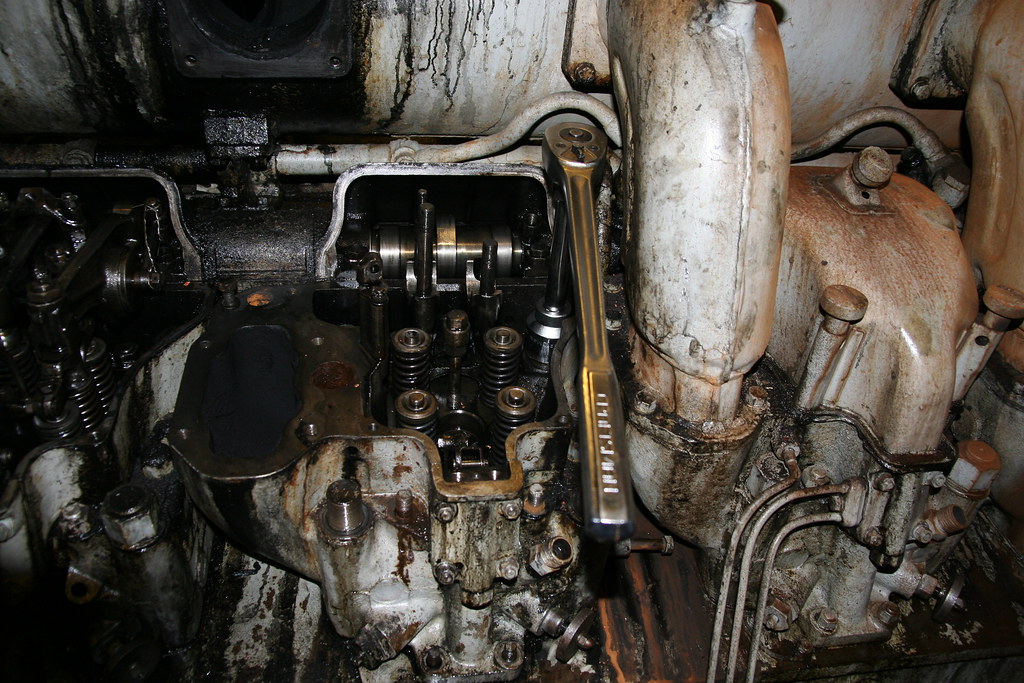

Covers & fuel lines (and overspeed) off.

Exhaust jumper and rockers off. Note the hole on top of the exhaust. The jumpers are all water cooled. You can lay your hand on them while shes running.

Parts & Tools.

Pulling the head. 4x 1 11/16" nuts, 650ft lbs each. Not fun finding that socket on the fly. We wound up using a torque multiplier, pretty much a 4:1 planetary drive. More on that later.

Heads off, fire ring in Matt's hand.

Old head gasket, upper jumper gasket and an O ring from the head.

The head.

Main bearings off.

New gasket kits.

Our patented liner-pulling thing.

The failed rings caused carbon to build up around the liner...time for heat. We maxed out a 1klb air winch. They outta make glue from that shit.

Up she comes.

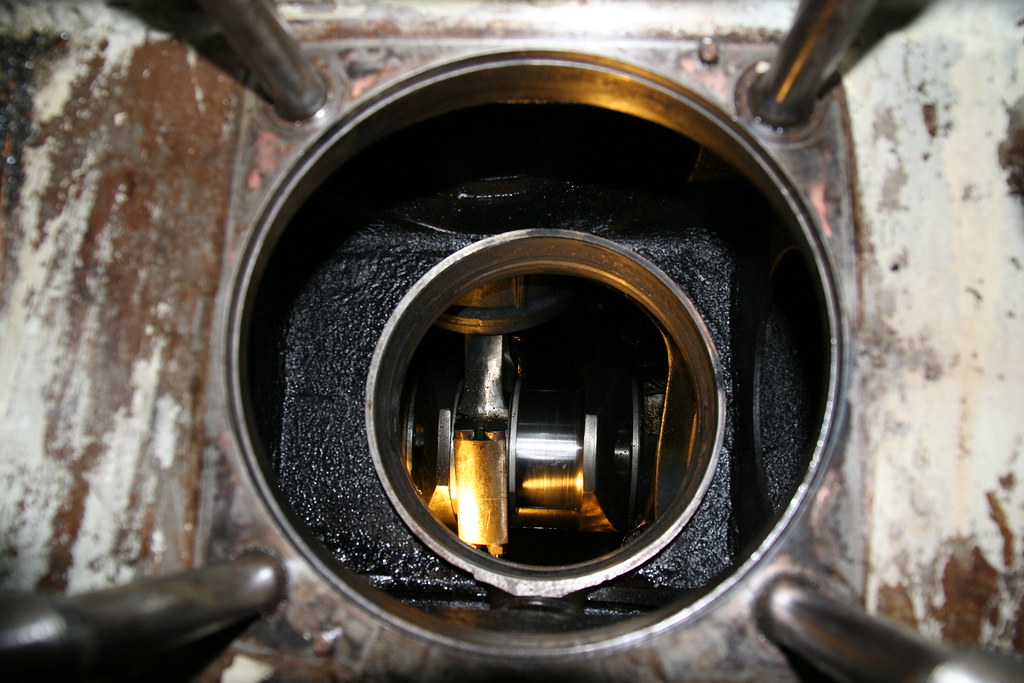

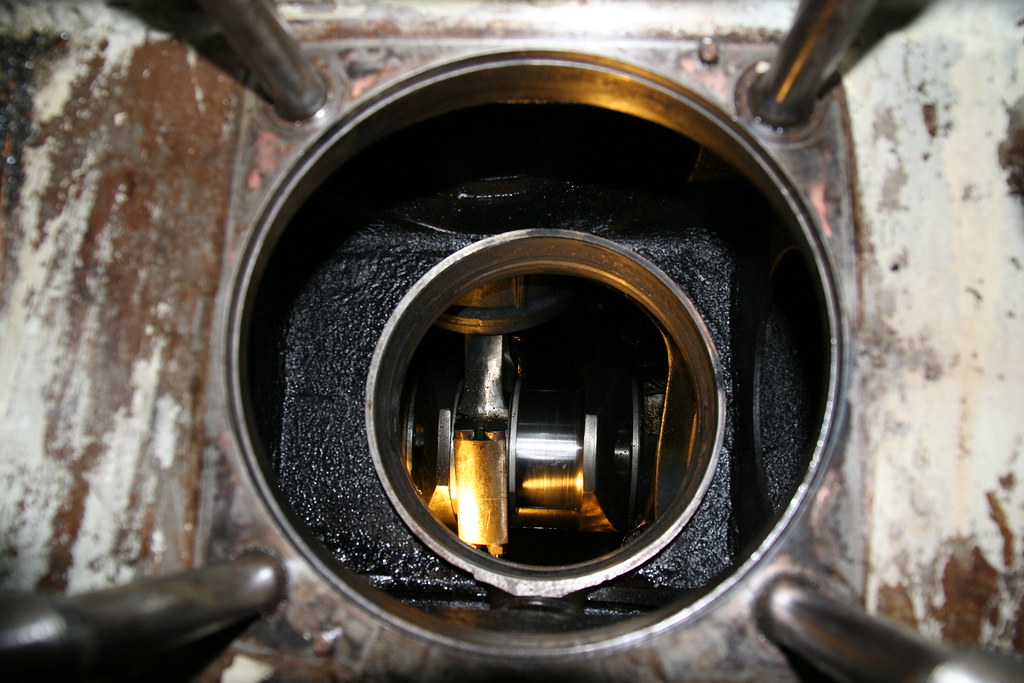

Liners out.

In the airbox..and crank case.

The O rings were permatexed in so they would not roll when installing.

In she goes.

New gasket and rings.

Putting the head back on.

Injector and fuel rod.

Going back together. You need to take the cover off the #5 cylinder to get clearance to the jumper bolts.

Old ring and multiplier.

Time to rebolt the connecting rod caps on.

Done..

Anyone have any tips on how to degrease a camera?

Well, last Tuesday..

We had a fire ring fail on the Cornell. On the 278A there is a copper fire ring on top of the cylinder, outside of which is the head gasket. The fire ring failed causing the O rings on the water jumpers between the liner and head to melt, which caused exhaust gas to get into the water side (causing the expansion tank to let off a few times before we got to it). We had the parts overnighted from Hatch & Kirk in Seattle WA....well, we tried..After spending the better part of a day trying to find a supplier (Thanks P)..we ordered the kit for rush overnight...guy forgot to place the order at H&K. After a few phone calls over Chinese dinner finding out where they are we got them the next day. We also redid the liner O rings as well while it was apart.

Anyway..

Draining the engine down.

Covers & fuel lines (and overspeed) off.

Exhaust jumper and rockers off. Note the hole on top of the exhaust. The jumpers are all water cooled. You can lay your hand on them while shes running.

Parts & Tools.

Pulling the head. 4x 1 11/16" nuts, 650ft lbs each. Not fun finding that socket on the fly. We wound up using a torque multiplier, pretty much a 4:1 planetary drive. More on that later.

Heads off, fire ring in Matt's hand.

Old head gasket, upper jumper gasket and an O ring from the head.

The head.

Main bearings off.

New gasket kits.

Our patented liner-pulling thing.

The failed rings caused carbon to build up around the liner...time for heat. We maxed out a 1klb air winch. They outta make glue from that shit.

Up she comes.

Liners out.

In the airbox..and crank case.

The O rings were permatexed in so they would not roll when installing.

In she goes.

New gasket and rings.

Putting the head back on.

Injector and fuel rod.

Going back together. You need to take the cover off the #5 cylinder to get clearance to the jumper bolts.

Old ring and multiplier.

Time to rebolt the connecting rod caps on.

Done..

Anyone have any tips on how to degrease a camera?