by bengt

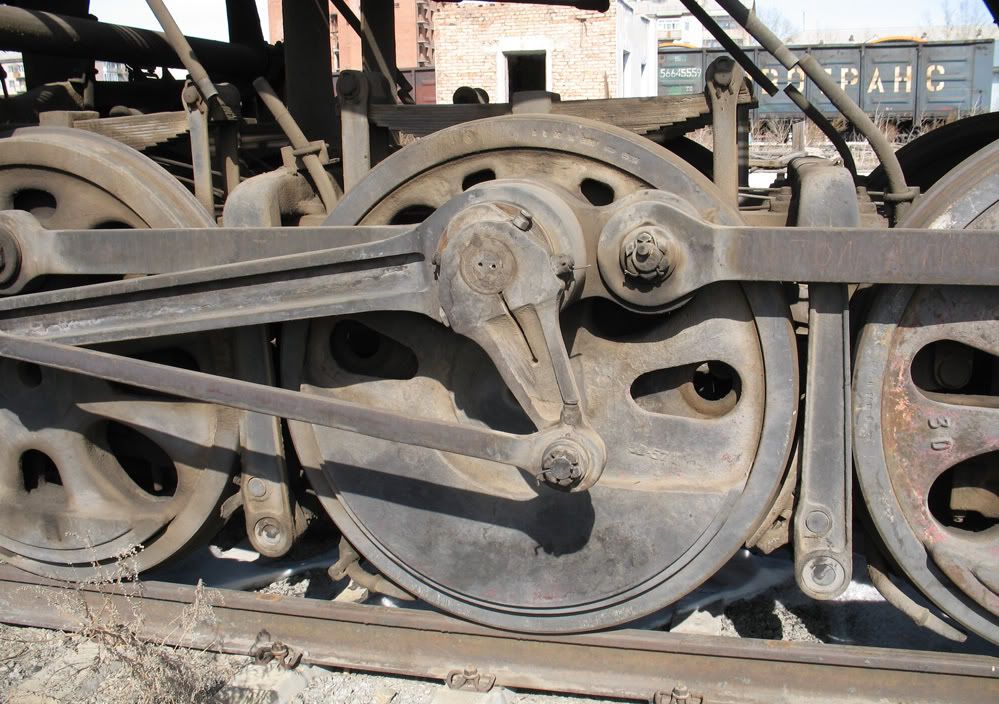

When in Zabalkalsk in Siberia at the border to China I saw some L-class locos. The bearings apear to have been grease lubricted.

To me it was the very first time I saw grease lubricated steam locos.

On the upper picture it is a bushing (or a cover protecting the crank pin?) with a lot of holes on.

If it is a bushing, had american grease lubricated bushings also such holes?