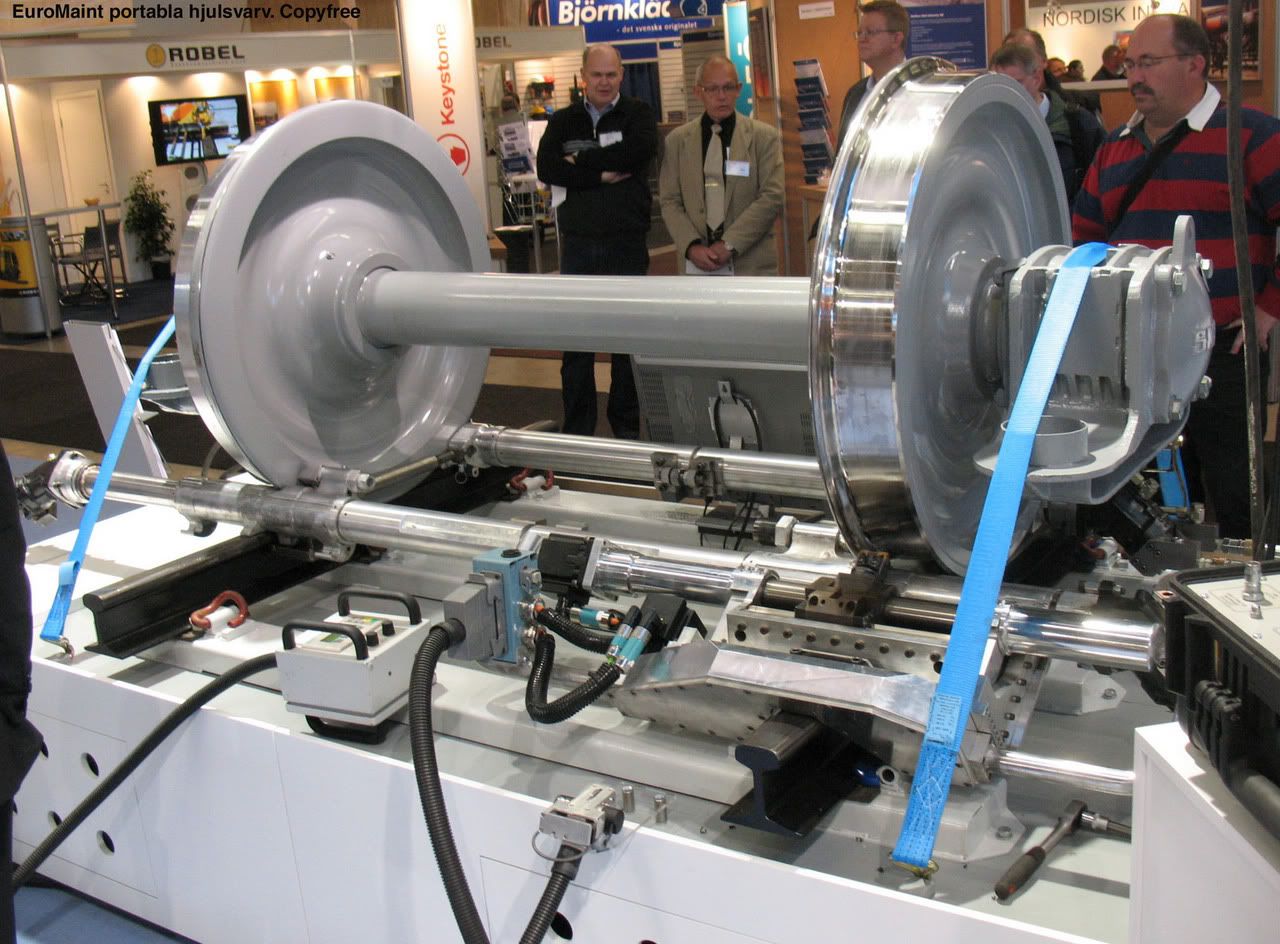

How are wheels profiled now? Are they ground or cut with a

lathe? Is there any hardening process in use to extend life?

lathe? Is there any hardening process in use to extend life?

Railroad Forums

Moderator: John_Perkowski

onder wrote:How are wheels profiled now? Are they ground or cut with a

lathe? Is there any hardening process in use to extend life?