For those who did not notice:

RS-1 467 will apparently live on in LIRR colors..... in Indiana......

http://www.railroad.net/forums/viewtopi ... c&start=15

Railroad Forums

**LONG ISLAND PRESERVATION NEWS**

- Discussion of the past and present operations of the Long Island Rail Road.

Moderator: Liquidcamphor

A picture of 467, big numbers and all........

http://www.trainsarefun.com/lirr/lirrRS ... 1-7-50.jpg

http://www.trainsarefun.com/lirr/lirrRS ... 1-7-50.jpg

Thanks Jason, guess the cat's out of the bag..... :o)

The 467, if and when she moves, will go to Tichy, and will be hauling the 2937 in original paint. Currently the 467 is blocked in by storage cars, this may not change for a few months. Brakes will be done soon, and whether she moves on her own wheels or replacement rollers will be determined in the coming months.

The 2937 will receive a complete exterior AND interior restoration - we have sourced good 3-2 walkovers for her. She will have new glass windows, and the exterior restoration will include sandblasting the entire car, as well as metalwork to repair the carbody. She will receive a high quality "automotive" style paint job! Overall she is in excellent condition, floor is solid throughout. Rides very well good track or bad. New replacement Hyatt KY's for what will be a very "original" looking car when done. Watch for pictures in progress and completion of the exterior work around Labor Day.

2001/2016 will join her as well if all goes OK, sometime by mid-summer.

Enough said - no questions please.

Thanks.

Fred.

The 467, if and when she moves, will go to Tichy, and will be hauling the 2937 in original paint. Currently the 467 is blocked in by storage cars, this may not change for a few months. Brakes will be done soon, and whether she moves on her own wheels or replacement rollers will be determined in the coming months.

The 2937 will receive a complete exterior AND interior restoration - we have sourced good 3-2 walkovers for her. She will have new glass windows, and the exterior restoration will include sandblasting the entire car, as well as metalwork to repair the carbody. She will receive a high quality "automotive" style paint job! Overall she is in excellent condition, floor is solid throughout. Rides very well good track or bad. New replacement Hyatt KY's for what will be a very "original" looking car when done. Watch for pictures in progress and completion of the exterior work around Labor Day.

2001/2016 will join her as well if all goes OK, sometime by mid-summer.

Enough said - no questions please.

Thanks.

Fred.

Gentle Forum Members,

The Trustees of the Railroad Museum of Long Island are pleased to announce that work is proceeding on Engine #39’s boiler at the erecting shops of the Strasburg Railroad Company, Strasburg, Pennsylvania.

On Tuesday, August 5th the boiler was loaded on Boilermatic Industrial Welding’s low boy tractor and trailer for the trip to Strasburg.

Boilermatic Industrial Welding of Medford, NY remains the lead contractor on this Suffolk County Department of Public Works project. From the beginning Strasburg has been Boilermatic’s consultant on the restoration of 39’s boiler and remains a sub-contractor.

On Monday, August 18th I had the pleasure of meeting with Shop Foreman, Rick Musser and President & Chief Mechanical Officer, Linn Moedinger to go over the work Strasburg has begun.

At this point in the project we will be focusing on the rebuild of the Belpaire firebox. Like the PRR K4s #1361, our LIRR G5s #39 firebox suffers from the same faulty Pennsylvania Railroad design. The thickness of the roof sheet is too small for the distance between staybolts on top of the firebox. Calculations by today’s FRA standards, with this design structure, give us less than a 180 psi operating pressure. A normal G5s operating pressure is around 208 psi with a design structure of between 211 – 215 psi.

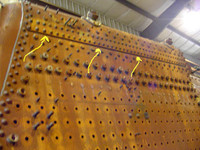

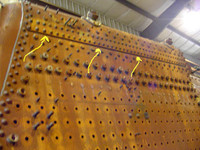

Strasburg will replace our roof sheet with new, heavier steel and/or more staybolts to bring the assembly up to FRA standards necessary to operate at our required pressures. Note the horizontal seam outlined by the yellow arrows. This seam is where the new roof sheet will begin and go up over the top of the firebox to the seam on the other side.

It is common knowledge that the Pennsylvania Railroad used “dirty” steel in the construction of their engines. Impurities and elements contained in this steel are notorious for giving unreliable UT readings. Strasburg has had experience working with this “Pennsy Steel” and knows what to look for in the UT readings and adjust accordingly for the variations.

Here we see a fresh grid has been laid out across the boiler. New Ultrasonic Thickness (UT) readings are being taken and documented by Strasburg for work on the vessel and the FRA Form 4.

A new backhead, door sheet and side sheets will be fabricated and installed. Following is the existing backhead, to be replaced by Strasburg.

This photo shows the INSIDE of the backhead. Note the welding seam above the sill outlined with yellow arrows. It appears the LIRR did a repair to the lower section of the backhead at one time, replacing the lower section and sill.

This neatly cut examination hole in the crown sheet will be repaired to FRA specifications with a deep penetration welded patch. The support rods and staybolts within will be replaced along with the new roof sheet.

Inside the yellow circle we see a broken support rod. All of the existing side support rods will be examined for strength before being reused. Critical areas of the support rods will be x-rayed for cracks and stresses. Faulty rods will be replaced.

The newly restored tender for Engine #39. This fine work was completed at the Boilermatic Industrial Welding shops located in Medford, New York.

Engine #39’s new fuel oil tank. Boilermatic Industrial Welding, Medford, New York.

We are very happy to have the project moving forward again after a hiatus of several months. That being said, as with any major steam restoration project there is never enough money to do everything we need or want to do when we want to or need to do it. Engine #39 is no different and I have stated on numerous Forum threads the need for additional funding to complete the drive train, brake system and locomotive frame components. Donations large or small for this restoration project will always be appreciated.

My next visit to Strasburg will be over the weekend of October 18 and 19. I will prepare a report first for the RMLI Trustees and then offer up those observations to the Forum in the weeks following. Sometime in late November or early December the Trustees of the Museum hope to make a one day trip down to view the progress of work on the boiler. Maybe, by then, we will have some exciting news about additional funds that have come in to keep the restoration on track. With your collective support and hard work, it may be so.

That’s all for now on #39.

de Don n2qhvRMLI

The Trustees of the Railroad Museum of Long Island are pleased to announce that work is proceeding on Engine #39’s boiler at the erecting shops of the Strasburg Railroad Company, Strasburg, Pennsylvania.

On Tuesday, August 5th the boiler was loaded on Boilermatic Industrial Welding’s low boy tractor and trailer for the trip to Strasburg.

Boilermatic Industrial Welding of Medford, NY remains the lead contractor on this Suffolk County Department of Public Works project. From the beginning Strasburg has been Boilermatic’s consultant on the restoration of 39’s boiler and remains a sub-contractor.

On Monday, August 18th I had the pleasure of meeting with Shop Foreman, Rick Musser and President & Chief Mechanical Officer, Linn Moedinger to go over the work Strasburg has begun.

At this point in the project we will be focusing on the rebuild of the Belpaire firebox. Like the PRR K4s #1361, our LIRR G5s #39 firebox suffers from the same faulty Pennsylvania Railroad design. The thickness of the roof sheet is too small for the distance between staybolts on top of the firebox. Calculations by today’s FRA standards, with this design structure, give us less than a 180 psi operating pressure. A normal G5s operating pressure is around 208 psi with a design structure of between 211 – 215 psi.

Strasburg will replace our roof sheet with new, heavier steel and/or more staybolts to bring the assembly up to FRA standards necessary to operate at our required pressures. Note the horizontal seam outlined by the yellow arrows. This seam is where the new roof sheet will begin and go up over the top of the firebox to the seam on the other side.

It is common knowledge that the Pennsylvania Railroad used “dirty” steel in the construction of their engines. Impurities and elements contained in this steel are notorious for giving unreliable UT readings. Strasburg has had experience working with this “Pennsy Steel” and knows what to look for in the UT readings and adjust accordingly for the variations.

Here we see a fresh grid has been laid out across the boiler. New Ultrasonic Thickness (UT) readings are being taken and documented by Strasburg for work on the vessel and the FRA Form 4.

A new backhead, door sheet and side sheets will be fabricated and installed. Following is the existing backhead, to be replaced by Strasburg.

This photo shows the INSIDE of the backhead. Note the welding seam above the sill outlined with yellow arrows. It appears the LIRR did a repair to the lower section of the backhead at one time, replacing the lower section and sill.

This neatly cut examination hole in the crown sheet will be repaired to FRA specifications with a deep penetration welded patch. The support rods and staybolts within will be replaced along with the new roof sheet.

Inside the yellow circle we see a broken support rod. All of the existing side support rods will be examined for strength before being reused. Critical areas of the support rods will be x-rayed for cracks and stresses. Faulty rods will be replaced.

The newly restored tender for Engine #39. This fine work was completed at the Boilermatic Industrial Welding shops located in Medford, New York.

Engine #39’s new fuel oil tank. Boilermatic Industrial Welding, Medford, New York.

We are very happy to have the project moving forward again after a hiatus of several months. That being said, as with any major steam restoration project there is never enough money to do everything we need or want to do when we want to or need to do it. Engine #39 is no different and I have stated on numerous Forum threads the need for additional funding to complete the drive train, brake system and locomotive frame components. Donations large or small for this restoration project will always be appreciated.

My next visit to Strasburg will be over the weekend of October 18 and 19. I will prepare a report first for the RMLI Trustees and then offer up those observations to the Forum in the weeks following. Sometime in late November or early December the Trustees of the Museum hope to make a one day trip down to view the progress of work on the boiler. Maybe, by then, we will have some exciting news about additional funds that have come in to keep the restoration on track. With your collective support and hard work, it may be so.

That’s all for now on #39.

de Don n2qhvRMLI

Twin Forks Hack 60..

Sparkle..

Not to much left..Lettering will be done shortly, windows will be replaced and the frames will be repainted silver.

Not to much left..Lettering will be done shortly, windows will be replaced and the frames will be repainted silver.

Sparkle..

Not to much left..Lettering will be done shortly, windows will be replaced and the frames will be repainted silver.

Not to much left..Lettering will be done shortly, windows will be replaced and the frames will be repainted silver.The paint looks great! How will the lettering be applied?

----------------------------------------------

Moderator: New York State Railfan :: New York Central :: Toy Trains

NYW&B Fan Site :: A Magazine I Read Often :: A Museum I Volunteer At

Moderator: New York State Railfan :: New York Central :: Toy Trains

NYW&B Fan Site :: A Magazine I Read Often :: A Museum I Volunteer At

Not 100% sure but I do believe they will be Vinyl. The original font/lettering was traced last year and they will be worked from that.

So what is going on with 39, other than the boiler?

Several times it has been mentioned that $150,000.00 is needed for the running gear and frame etc. What exactly needs to be done? Specifics please......

And what about the rest of the collection? and the turntables? etc????

What are RMLI's current plans? What's on the drawing boards?

Several times it has been mentioned that $150,000.00 is needed for the running gear and frame etc. What exactly needs to be done? Specifics please......

And what about the rest of the collection? and the turntables? etc????

What are RMLI's current plans? What's on the drawing boards?

Engine 39 Report from Strasburg

Friday, November 14, 2008

On Friday, November 14, 2008 I met with Rick Musser at the Strasburg Railroad Company to see the progress of work on the firebox of Engine 39. I had originally posted that I would get back to Strasburg for a report in October, but with my work schedule filled I wasn’t able to break away until this past weekend. I am pleased to report that much has occurred on the firebox since my visit three months ago on August 19.

From this photo we see that the roof sheet and upper side sheets have been cut away and removed from the Belpaire firebox. The roof sheet was removed because it is too thin for the “bolt pitch,” the number of and distance between staybolts supporting the sheet. The roof sheet will be replaced with thicker steel to make up for the bolt spacing, “pitch.” Additionally, this allowed for easy inspection of the support rods, backhead braces and the composition of the side sheets. Note the numerous bare spots and numbers on the backhead.

In August a chalk line grid had been drawn upon the boiler in preparation for Ultrasonic Testing (UT). Since August, grids have been placed on all parts of the boiler and firebox and UT readings have been taken and recorded. It is from these readings that decisions are made on what to repair and what to replace.

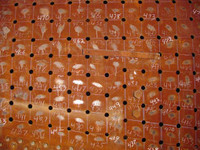

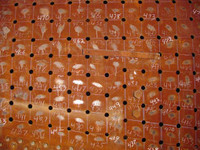

In this photo of 39’s side sheets, note the polished metal evenly spaced between each staybolt hole. It is here that the UT readings are taken. The visible chalk number is the thickness reading found at that location.

UT readings and their numerical findings cover the rear flue sheet and inside the crown sheet.

Here we see photos of the many support rods, (backhead braces), that have been uncovered by removal of the too thin roof sheet. These rods will be Magnaflux tested for soundness. You may recall that during my August visit one of these rods had been shown to be broken, that rod and any other rods that do not pass testing will be manufactured and replaced by Strasburg.

Inspection of the side sheets has uncovered quite a lot of steel impurities or laminations, (“dirty steel”).

Here, Rick Musser points to evidence of lamination in the steel plate. The laminations must be removed and repaired by welding so the material is "sound" as per the National Board Inspection Code. If the laminations are too extensive, the side sheet will be replaced.

You may remember my discussion in August about the “dirty steel” being used in Pennsy locomotives of the time. Welding must be done only on material that shows no evidence of laminations. To check the steel for impurities before welding, the craftsman employs a Magnaflux machine. Seen above, the appliance sets up a tremendous magnetic field around and through the material being tested. A powder composition of iron filings is cast upon the edge of the material. Wherever there are laminations, the filings collect and create a pattern that “illuminates” it. Further cutting and/or grinding is done to see how far the impurity extend into the sheet. If there is extensive deep penetration of impurities and it becomes impossible to find good steel to weld on the old material is replaced.

The old upper side sheets and roof sheet, removed from the firebox, rests outside at the Strasburg Railroad Company Erecting Shop.

Before the roof and side sheets were removed, Masonite templates were made to assist in the formation of the new side sheets and roof sheet.

Here we see the troublesome area of #39’s roof sheet. (Also a problem area affecting the restoration of Pennsy K4s #1361.) As discussed in August, due to Pennsy design characteristics, the pitch of the staybolts supporting the 3/8” thick roof sheet lowered the locomotive’s acceptable operating pressure below the normal 208 lbs. To correct this issue, new 1/2” thick steel plate will be used to replace 39’s roof sheet - increasing the structural strength to support an acceptable operating pressure.

A final photo of historical interest. In the lower right hand corner of the firebox is a stamping placed there by Pennsylvania Railroad Craftsmen at the time Engine 39’s boiler was built. It reads:

NEW BOILER

JL SHOPS

6-27-29.

Submitted: 18 November 2008

Don Fisher

Friday, November 14, 2008

On Friday, November 14, 2008 I met with Rick Musser at the Strasburg Railroad Company to see the progress of work on the firebox of Engine 39. I had originally posted that I would get back to Strasburg for a report in October, but with my work schedule filled I wasn’t able to break away until this past weekend. I am pleased to report that much has occurred on the firebox since my visit three months ago on August 19.

From this photo we see that the roof sheet and upper side sheets have been cut away and removed from the Belpaire firebox. The roof sheet was removed because it is too thin for the “bolt pitch,” the number of and distance between staybolts supporting the sheet. The roof sheet will be replaced with thicker steel to make up for the bolt spacing, “pitch.” Additionally, this allowed for easy inspection of the support rods, backhead braces and the composition of the side sheets. Note the numerous bare spots and numbers on the backhead.

In August a chalk line grid had been drawn upon the boiler in preparation for Ultrasonic Testing (UT). Since August, grids have been placed on all parts of the boiler and firebox and UT readings have been taken and recorded. It is from these readings that decisions are made on what to repair and what to replace.

In this photo of 39’s side sheets, note the polished metal evenly spaced between each staybolt hole. It is here that the UT readings are taken. The visible chalk number is the thickness reading found at that location.

UT readings and their numerical findings cover the rear flue sheet and inside the crown sheet.

Here we see photos of the many support rods, (backhead braces), that have been uncovered by removal of the too thin roof sheet. These rods will be Magnaflux tested for soundness. You may recall that during my August visit one of these rods had been shown to be broken, that rod and any other rods that do not pass testing will be manufactured and replaced by Strasburg.

Inspection of the side sheets has uncovered quite a lot of steel impurities or laminations, (“dirty steel”).

Here, Rick Musser points to evidence of lamination in the steel plate. The laminations must be removed and repaired by welding so the material is "sound" as per the National Board Inspection Code. If the laminations are too extensive, the side sheet will be replaced.

You may remember my discussion in August about the “dirty steel” being used in Pennsy locomotives of the time. Welding must be done only on material that shows no evidence of laminations. To check the steel for impurities before welding, the craftsman employs a Magnaflux machine. Seen above, the appliance sets up a tremendous magnetic field around and through the material being tested. A powder composition of iron filings is cast upon the edge of the material. Wherever there are laminations, the filings collect and create a pattern that “illuminates” it. Further cutting and/or grinding is done to see how far the impurity extend into the sheet. If there is extensive deep penetration of impurities and it becomes impossible to find good steel to weld on the old material is replaced.

The old upper side sheets and roof sheet, removed from the firebox, rests outside at the Strasburg Railroad Company Erecting Shop.

Before the roof and side sheets were removed, Masonite templates were made to assist in the formation of the new side sheets and roof sheet.

Here we see the troublesome area of #39’s roof sheet. (Also a problem area affecting the restoration of Pennsy K4s #1361.) As discussed in August, due to Pennsy design characteristics, the pitch of the staybolts supporting the 3/8” thick roof sheet lowered the locomotive’s acceptable operating pressure below the normal 208 lbs. To correct this issue, new 1/2” thick steel plate will be used to replace 39’s roof sheet - increasing the structural strength to support an acceptable operating pressure.

A final photo of historical interest. In the lower right hand corner of the firebox is a stamping placed there by Pennsylvania Railroad Craftsmen at the time Engine 39’s boiler was built. It reads:

NEW BOILER

JL SHOPS

6-27-29.

Submitted: 18 November 2008

Don Fisher

Last edited by n2qhvRMLI on Tue Nov 18, 2008 9:56 pm, edited 1 time in total.

Wondeful Report Don! I am glad to see so much progress

Are we going to get the old meatal for a display...LOL

Thanks Don!

Anthony

Are we going to get the old meatal for a display...LOL

Thanks Don!

Anthony

So steam heat for Riverhead Next Year? We all can hope. I miss the boiler to bad it wont be home for a while  . To bad there was not a ping preserved so detail pictures of the 39's restoration could be put up in it with other displays about Long Islands rich railroad history.

. To bad there was not a ping preserved so detail pictures of the 39's restoration could be put up in it with other displays about Long Islands rich railroad history.

Mike

Mike