Guess I can add some additional informations, because coasting of steamers and the methods used, can be very interesting.

First one must understand, why coasting is so problematic in steam locomotives, or in any other steam engine case.

If the driver runs the engine with the throttle open, steam enters the cylinder, controlled by the valve gear, through the steam chest and the cylinder slits or cylinder ports the cylinder space. Here if pushes the piston to the opposite wall. Now the gear switches the ports from inlet to outlet, and the steam can leave the cylinder room to the exhaust. This is supported by steam, which now enters on the opposite side of the piston an pushes it back to the point before, so also pushes the expanded steam through the ports connected to the outlet into the exhaust.

And now the driver shuts the throttle, and the train behind the loco starts pushing the loco further forward. This acts like a giant flywheel, making the pistons still move, but now being moved by the wheels, rods and bars, and not by steam power.

This will result in having a gas tight piston in motion, so a engine will get a pump. So each time, when under steam the steam would push the piston, now as pump the piston would try to draw something in, but there is nothing to aspirate, so the piston starts to generate a more or less high vacuum or negative pressure in the steam chest, the super heater tubes and the main steam pipes up to the throttle valve. So this can lead to serious damage, like dented super heater tubes or a dented main steam pipe inside the boiler. More serious is, the vacuum effects will often relieve the throttle valve, so this may open a little, and this could damage the throttle valve main seal seat, so a general leaking of this adjustable valve would have serious effects in driving the locomotive.

On stationary engines those effects are medium serious, because the engine generated a vacuum, but this will slow down the flywheel, which is usually itself slowed down by the connected power line transmissions, so the slow down effects are rather welcome, than problematic.

In locomotives those vacuum problems with the resulting brake effects become serious, because on downhill ride the braking effect may also harm the engine, as well as disturbing the free coasting of the engine.

So in the beginning of the age of steam on railroads, the engines opened the throttle downhill a little bit. This so called "grease steam" cooler the cylinder bore and piston, as it helped to bring oil to the cylinder liners, preventing the liner becoming deoiled and getting problematic because of increasing friction.

So engineers mounted sniffer valves to the main steam tube or at the steam chest, mainly to locomotives with piston valves. In locomotives with allan-trick-valves the valve body simply lifted from it's lining surface and a pressure balance was given, by quickly drawn in air through the open chimney.

But this resulted in often ash particles and dust particles being drawn into the valve box and thus increasing friction and maybe damaging the liners and lining surface by rubbing on it.

So even here, sniffer valves were mounted, to prevent such problems. First those valves were manually operated. Shutting the throttle and then opening the sniffing valve, to open a bore to the free air, connecting steam chest and open air together. Surely, this lead to further problems, because if the manual open shut mechanism was damaged, the throttle open much steam left through the sniffer valve bores into free air, often the engine wasn't able to go on power.

So self closing valves were the next step of development. the valve was a two part seal: the top part was a valve with a ring seal for the fresh air, the lower valve was a small round lid. If the engine was running under pressure, the throttle open, the lid was hovering on the steam, and was pressed by the steam pressure in the body of the valve to a ring shaped seal seat. Throttle shut, the pressure in the valve decreased and the lid dropped by gravitation to a small seat below, open the channels to the air valves. Small bores helped to overcoming a vacuum effect, but coasting was only able, if the air valve was manual opened.

Later the lid becomes spring loaded and the manual operation now had to open the air channels to the sniffer valve, as to overcome the spring load and pushing the lid to the seat below, opening the sniffer valve for anti-vacuum effects and a free coasting of the engine.

From that point, those sniffer (now called snifter of sniffing valves, because being able so self seal under pressure, making a distinct sound if being shut by streaming steam into the valve body) valves were also opened or closed with pneumatic pressure. Some still mounted on the steam chest, other on the outlet of the superheater throttle valve, or onto the cylinder itself.

The latest development is the anti-vacuum piston valve.

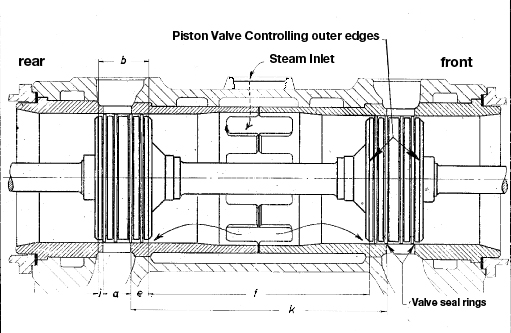

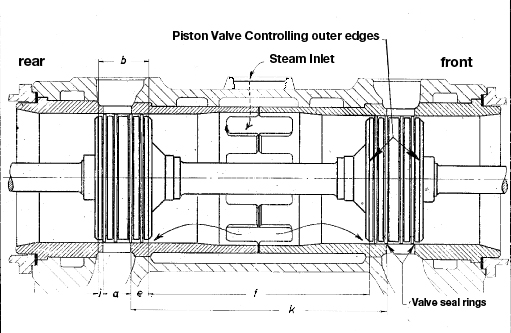

The piston valve is a rod with two pistons mounted in a fixed distance on the rod. The outer edges open or seal the steam ports to the cylinder.

So the first experiment come from the prussian railways, which build a anti-vacuum piston valve to a prussian tank engine, which was developed by the Vulcan Engine Works in Stettin.

Unfortunately war and the upset of the Deutsche Reichsbahn Gesellschaft during the pre and past WW2 times made this project nearly forgotten.

Also other engineers developed anti-vacuum piston valves, like Mueller and Nicolai. Nicolai was a jew, so his name was erased from the technical drawings and developers list and Karl Schulz was instead named as founder of this anti-vacuum piston valve.

This was a spring loaded anti vacuum piston valve, the later Mueller was without springs, and the last was developed in the former Soviet Republic by the engineer Trofimov.

Let's have a look at the Nicolai and Mueller valve.

As visible in the drawing the piston valve has to bodies, one front and one rear.

With the piston outline the piston valve seal or open the ports to the cylinder.

In the Nicolai valve, the piston valve body was split. So two halves formed the piston body. As steam entered, the two halves were pushed together against the spring load, so act like a common piston valve. Was the throttle shut and the pressure in the steam chest low or absent, the spring pushed the two halves a little bit apart and now both cylinder sides, rear and front were connected together, resulting in a very good idle of the engine, making the loco coast much better.

Broken springs in the Nicolai valve made this Valve often failing, so anti vacuum effect were not good at all, till completely absent, so the Mueller piston valve was the solution. Here the piston body wasn't made of two moveable halves, the two halves were now one body with a ring shaped valve lid on the inner side of each piston body. Under pressure, the lid ring was pressed against the ring seal of the piston body, letting the piston act as a common piston valve. Without pressure in the steam chest, the lid flipped open by the motion of the piston valve itself, and the anti-vacuum effect was given.

Also there are some main backdraws, like difficult anti vacuum lid seal or breaking or bending of the lid, resulting in a complete failure of anti vacuum and improper valve gear function.

This was overcome with the development of the anti vacuum piston valve of Trofimov.

The discussion if his name is spelled Trofimow, Tovimow, or Trofimov is obsolete, because the German Democratic Replublic spelled him Trofimov, and that's how this piston valve is found in the maintenance and construction instructions.

So, as mentioned before, in Stettin the Vulcan company developed a anti vacuum piston valve. This was simple: The bodies of the pistons were no more fixed to the valve rod. Only two carriers were left fixed on the rod.

So under pressure, the bodies of the pistons were pressed to the outside ends of the rod, hit the carriers and acted as a fixed piston valve gear in normal construction design. As pressure in steam chest decreased, the carriers shifted the bodies of the pistons more and more to the inner middle of the valve liner tube, so the ports of the cylinder were finally and complete connected through the exhaust box body and channels.

The valve bodies hat holes, just to prevent the piston bodies to hit the carriers hard by opening the throttle, leading to certain steam leakage problems, but did not really let the valve gear fail. Broken carriers were problematic, but uncritical for the locomotive function and the over all very good coasting made this valve superior.

Trofimov found after WW2 the development and construction drawings, and because knowing of the problems with the Nicolai valve, he used the Vulvan design and improved the construction.

As visible in the picture above, the carrier was removed to a outside, screw locked stopper. The whole valve piston body is loose on the valve rod, with some leading edges.

Under steam, the pressure in the steam chest pushes the piston valves bodies outwards against the stopper. So the piston valves act like a normal fixed piston valve. If steam was shut of, the stoppers pushed the bodies to the middle of the valve liner tube, while the rod was running freely through the piston body central axis. That opened again the full area of the cylinder ports and connected them together, resulting in optimum anti vacuum effect, while also ensuring the possibility to get the gears back to mid gear after anti vacuum.

Today the Trofimov at many museal locomotives is used, and improved constructions are available, making the valve going into anti vacuum position much better and returning to operation position much earlier than the elder constructions.

So how was that in the US? Are there anti vacuum piston valves ? Which function and design? Of are there still sniffing valves used?

Allways keep two-thrid level in gauge and a well set fire, that's how the engineer likes a fireman